The mere suspicion that carbide is a brittle material had held back its use for quite some time, till a number of actual trials were conducted. It is some 50 years, since tests in the USA indicated that hard metal slips could outlast steel by at least ten times and in certain conditions even 100 times.

Features • Dimensional Stability

• Ability to Wring

• Resistance to Corrosion

• Resistance to Wear

• Economy

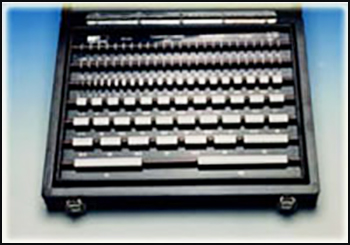

Mikronix Tungsten Carbide Slip Gauges are offered in metric sizes from 0.2mm to 100 mm and in inch sizes from 0.01 to 4 inches. They can be supplied in standard sets to meet any grade of national or international standard. The sets mentioned here are commonly used and manufactured by us; any other sets can be supplied against specific requirement. Metric sets are manufactured with 1mm & 2mm base. Sets of 2mm base are recommended by BS4311 for extra rigidity.

Metric Sets |

Inch Sets |

Set of 122 pieces (M122/1) |

Set of 81 pieces ( E81) |

Set of 41 pieces ( E41 ) |

|

Set of 36 pieces( E36 ) |

|

Set of 47 pieces (M47/1) |

Set of 9 pieces (E9 ) |

Set of 2 pieces ( E2 ) |

|

Set of 32 pieces (M32/1) (M32/2) |

|

Corrosion Resistant

• Unaffected by water, acids and alkalis.

• Simple maintenance with no requirements of any anti - corrosion treatment.

• No adverse effects due to fingering while using.

Resistant to IMPACT

• Zirconia ceramic blocks are hard and highly tough to withstand the knocks and drops that occur during use and will not chip or fracture easily

Resistant to WEAR

• About 10 times life or even more compared to steel slip gauges. The natural stability and durability due to its low friction co-efficient maintains their geometry longer.

Superior WRINGABILITY

• The uniform and close grain structure enables the blocks rigidly wrung together and easy to operate.

• Dents and burns are not easily produced on gauge surface.

THERMAL expansion

• Co-efficient of thermal expansion of ceramic is 10×10^-6/ºC is very close to that of steel by 1.5×10^-6/°C.

• The lowest thermal conductivity makes these gauge blocks easy to use at different temperatures.